- Published on

Waspr Project - Wennschon, dennschon

All in

- Authors

- Name

- Mr. Goferito

- @Mastodon

January 25 - Wennschon, dennschon

Playing with arduino is quite satisfying. I have just discovered what servo motors are. Essentially, they are motors that don't spin endlessly but instead they get a third wire connected with a specific current. Depending on the intensity of the current they point in one direction or another. They usually rotate a maximum of 180 degrees. I have tried to connect and rotate servo motors and it has turned out just as easy as with the LEDs. All tests I've done so far have worked just fine.

The plan still is to point the laser with a galvanometer. The difference is that now I want to try to make the galvanometer myself with the servos. I buy some mirrors on Amazon for 9 euros. It's 33 mirrors, but they don't sell smaller packs. Eirini asks me if I give her one mirror. I give her a few, I'm sure Sergio wants some too. I buy 5 servos (for 13 euros). I need two of them to build the galvanometer, and in the learning kit I only got one.

//TODO Add picture of mirrors and servos

I buy normal laser diodes for 1.15 euros 10 units (plus 32 euros shipping).

The question I have now is how to put all the pieces together, in the right positions. These days I've spent a lot of time looking for similar projects. Many use wood and glue to create the pieces they need to hold the motors, and make holes in the right positions to put screws, cables, or fit electronic components. Others, more pros, have amazing workshops and they work bending aluminum and drilling and cutting metal. An interesting solution to create the parts which support the motors and other electronic components is 3D printing. I would just have to learn first how to design 3D objects.

Fabio recommends TinkerCAD for designing simple parts. I take a look, and I try to design a simple piece, and yes, it's quite easy. I also look for some more sophisticated alternatives. I decide to try designing a piece in FreeCAD. FreeCAD is a lot more complete, and for complex pieces TinkerCAD wouldn't be enough. FreeCAD allows you to design objects in 2D and then give them height, add constraints such as that certain points have to match some other points or that certain angles can never change even if you change the size of a certain part, and so on. There are other alternatives to FreeCAD which are even more pro, but for now, what I want to do is simple enough to follow Fabio's recommendation.

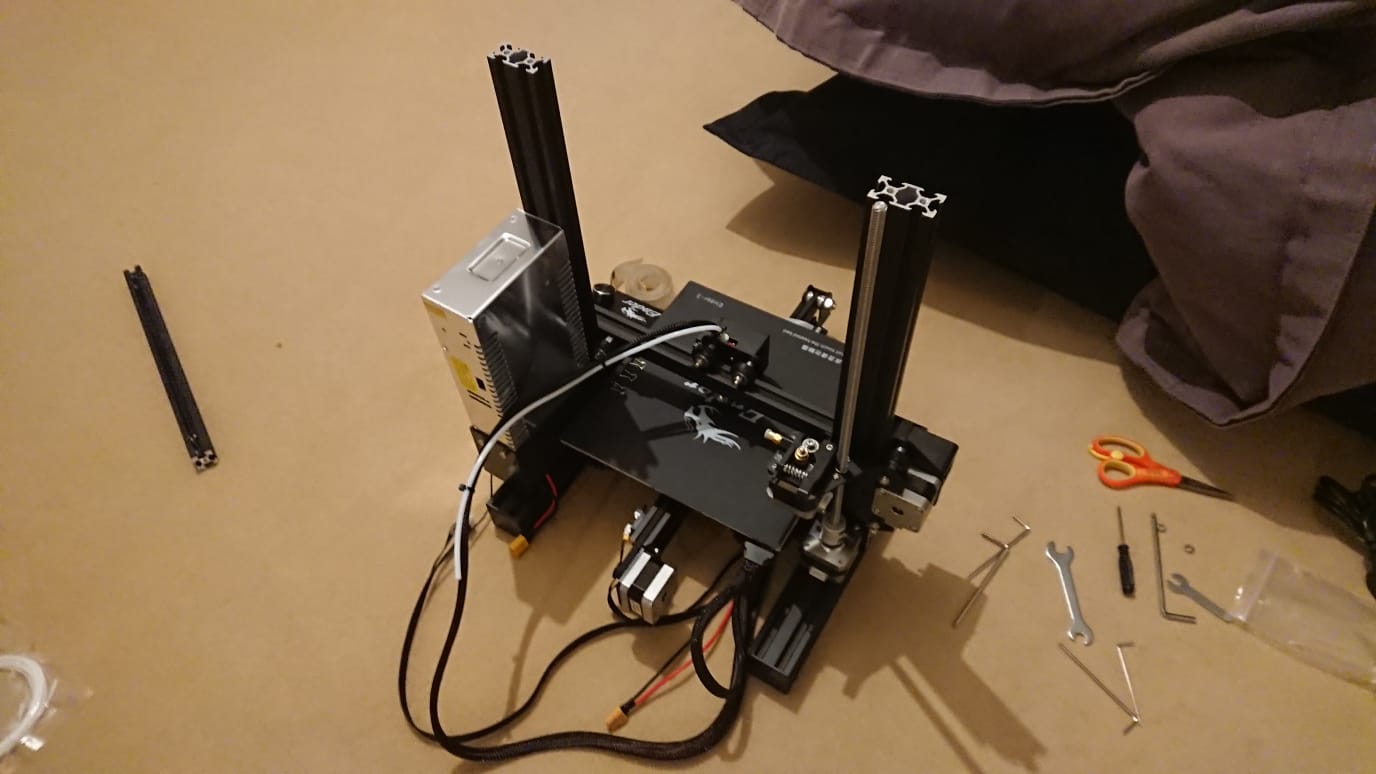

I look at options and prices on 3D printers. There are a lot of types, and subtypes, and subtypes of subtypes but made of different materials. I see videos on YouTube about the most common ones. A goal for this project is to learn new things. I decide to buy a pack of printer parts, instead of the printer already assembled, and thus learn a bit about the different parts on the fly. I buy the most common pack to assemble the most common printer, the Ender 3. People seem to be very happy with it. The pack costs 225 euros, plus 23 euros for a roll of PLA, a biodegradable material used for printing.

I receive everything at the office. Except for the lasers. The german customs asked me for 40 euros for them and I told them they better keep them. 40 euros of taxes for something that costs 1 euro? I will just get another laser somewhere else.

The pack comes with some pretty minimal instructions. I've got quite a few pieces and screws left over, and in the box there were tools that I didn't use at all. Either they have been very generous in sending extra pieces, or I have left something unscrewed. But now it's too late. Tomorrow I will try to see if the thing really works.